Jute, often hailed as the “golden fiber,” has a rich history deeply intertwined with human civilization. Its journey from plant to product is a fascinating narrative of sustainability, craftsmanship, and innovation. In this article, we delve into the intricate process of jute production, highlighting each step from harvesting the raw jute to creating the final products. Along the way, we’ll explore the techniques, technologies, and sustainable practices that make jute not just a versatile material but also an eco-friendly choice.

Section 1: Harvesting and Retting

The journey begins in the vast jute fields where skilled farmers carefully harvest the tall, slender jute plants. Harvesting is typically done by hand to ensure minimal damage to the fibers. Once harvested, the jute stalks undergo retting, a natural process where they are soaked in water to facilitate the separation of fibers from the woody stalks. This crucial step softens the outer layers of the plant, making it easier to extract the fibers. Sustainable practices come into play here, with many farmers opting for eco-friendly retting methods such as water retting, which reduces environmental impact compared to chemical retting.

Section 2: Fiber Extraction and Cleaning

After retting, the jute stalks are spread out to dry, allowing the fibers to loosen from the stalks. Once dried, the fibers are stripped from the stalks using specialized machines, separating the valuable jute fibers from the woody core. This process, known as stripping or ribboning, requires precision and care to ensure the fibers remain intact. Once separated, the fibers undergo thorough cleaning to remove any impurities or remaining woody particles. Sustainable practices such as using biodegradable detergents and water recycling systems help minimize environmental impact during this stage.

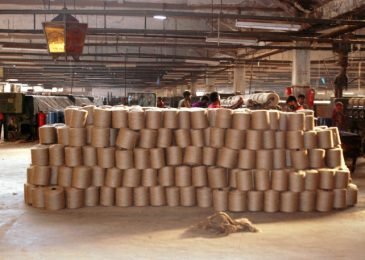

Section 3: Spinning and Yarn Production

With the fibers cleaned and prepared, they are ready for spinning. Spinning transforms the loose jute fibers into strong, durable yarns suitable for weaving and knitting. Traditional spinning wheels have been replaced by modern spinning machines, which offer greater efficiency and consistency in yarn production. These machines carefully twist the jute fibers together to create yarn of various thicknesses and qualities, depending on the intended use. Sustainable spinning techniques focus on energy efficiency and waste reduction, contributing to a greener jute industry.

Section 4: Weaving and Fabric Formation

Once spun, the jute yarns are ready to be woven into fabric. This weaving process involves interlacing the yarns to create intricate patterns and designs. Automated looms have revolutionized the weaving process, allowing for faster production and greater precision. Sustainable weaving practices prioritize the use of natural dyes and eco-friendly chemicals to minimize environmental impact. Additionally, efforts are made to reduce water and energy consumption during the weaving process, further enhancing the sustainability of jute fabric production.

Section 5: Product Manufacturing and Distribution

From woven fabric to finished products, the journey of jute culminates in the manufacturing stage. Skilled artisans and craftsmen transform jute fabric into a wide range of products, including bags, rugs, clothing, and home decor items. Sustainable manufacturing practices focus on fair labor standards, safe working conditions, and minimal waste generation. Once manufactured, jute products are distributed to markets worldwide, where consumers can appreciate the beauty, versatility, and eco-friendliness of this remarkable fiber.

The journey of jute from plant to product is a testament to human ingenuity and the enduring appeal of sustainable materials.

At every stage of production, from harvesting to manufacturing, efforts are made to minimize environmental impact and promote ethical practices. By choosing jute products, consumers not only support local communities but also contribute to a more sustainable future for our planet.